ENERGY

Turnkey Solutions Across the

Energy Value Chain

SPECIALIZED ENERGY INFRASTRUCTURE SOLUTIONS

A Proven Partner for Complex Energy Projects

At MIG, we enable essential infrastructures across the energy value chain- from natural gas processing to cryogenics, LNG, and biogas-to-renewable natural gas systems—with unmatched precision and accountability. From installation, construction, fabrication, and construction, to full lifecycle maintenance and emergency response, we deliver integrated solutions that maximize uptime, extend assets, and accelerate your energy transition.

Whether it's midstream gas compression, LNG cold chain, or biogas upgrading plants, MIG’s technical teams bring decades of operational insight, safety culture, and mission-critical delivery discipline. Partner with MIG and bring on a contractor that delivers more than services—delivers performance.

CONTACT US

Call us today to speak with one of our Energy Infrstructure specialists: +1 (317) 870-2400 or click to contact us below:

Engineering, Fabrication, & Construction

ENERGY INDUSTRY SERVICES & SOLUTIONS

-

Why MIG?MIG’s integrated teams of experienced licensed craftsmen, professional engineers, and highly trained workforce, along with its seasoned leadership team have earned a reputation for consistently delivering the highest quality solutions and services - at competitive prices – while maintaining an impeccable safety record.

Our experienced team of project managers, professional engineers, certified welders and fabricators, certified riggers, millwrights, pipefitters, valve technicians, specialty machinists, and support personnel deliver our services to the highest standards of quality and safety, improving facility reliability and performance—and supporting greater profitability for your plant.

Our ability to respond quickly to critical equipment failure and repair needs and deliver rapid response for confined space emergencies is unmatched.

-

Preventative MaintenanceOur preventive maintenance (PM) programs are tailored to the specific needs of your unique plant requirements. MIG's turnkey plant preventative maintenance solutions include regular inspections, routine maintenance, repair, and replacement services to enhance your refining or biofuels plant's performance—and greatly reduce the chance of equipment failure.

Our experienced refining/biofuels processing plant PM specialists design preventive maintenance programs that take your plant's unique piping and equipment, operating conditions, runtime, and other factors into account to develop individualized plans—and set accurate budgets—for predictable Capex planning.

Contact us today to learn more!

-

Equipment Installation & RepairMIG is an industry-leading provider of refining and biofuels plant process piping, vessels, tanks, and equipment installation services. We are an NBIC “R” Stamped company for repairs and alterations both at our shop and in the field. Our services include:

- All forms of piping materials: Stainless Steel, Stainless to Carbon, Carbon Steel, Aluminum, Monel, Inconel Certified Welders

- Emergency Maintenance repairs & alterations

- Field-based new installations and relocation

- Refining & biofuels process piping design, fabrication, installation, & repair

- General Contracting

- Orbital Welding

- Planned maintenance & turnarounds

- Plant Upgrades, Relocations, and shutdowns

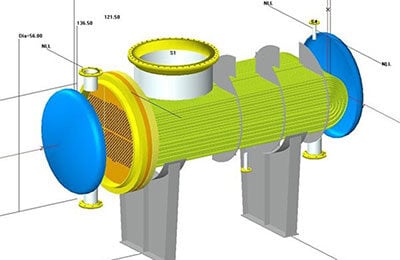

- Fabrication & installation of ASME pressure vessels, distillation columns & towers, reactors, TEMA heat exchangers, API storage tanks, and more

- R-stamp repair & modification projects on ASME pressure vessels, distillation columns & towers, reactors, TEMA heat exchangers, API storage tanks, and more

- More

-

Process Piping & TubingA MIG delivers expert fabrication, installation, maintenance, repair, upgrades, and replacement of refining & biofuels process piping and tubing systems used to convey hot and cold liquids, water, steam, and other fluids and gases - along with the installation of all related equipment and fixtures that store, pump, regulate, measure, and distribute these liquids and gases.

Our services span all you related needs including: piping, tubing, valves, pumps, motors, and other mechanical equipment necessary for the safe and efficient operation.

Learn more about our process piping & tubing installation & maintenance services here.

-

Welding & FabricationOur state-of-the-art fabrication facility combines cutting-edge equipment and technology with highly-skilled, experienced engineering and fabrication teams—offering the highest quality custom-engineered and fabricated solutions to clients in the refining & biofuels industries.

As a TransTech family company we leverage all company facilities and locations across the U.S. to execute and deliver refining and biogas processing plant projects cost-effectively, efficiently and to optimal schedules.

Learn about our custom fabrication solutions here.

-

Our CustomersWe have performed services for some of the largest pharmaceutical and food & beverage companies in the nation, including

- Asphalt Materials

- Civitas Resources Inc.

- Covanta

- Darpro

- Marathon Oil

- Pinnacle Oil

- Southampton Resources

- And more!

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

REFINING & BIOFUELS PLANT MRO SPECIALISTS

-webp.webp?width=284&height=219&name=MIG%20Flipbook%20Cover%20w%20Shadow%20(1)-webp.webp)