CONSTRUCTION

Turnkey Air Separation Construction

for Industrial Gas Plants

AIR SEPARATION UNIT CONSTRUCTION

From Groundbreaking to Commissioning

Maddox Industrial Group delivers air separation unit construction services that set the industry standard for reliability, safety, and speed. From greenfield sites to major plant expansions, we bring unmatched expertise in air separation construction to industrial gas producers, steel mills, chemical plants, and energy facilities across North America.

Why Choose MIG for Air Separation Construction

-

Turnkey Execution: Full-scope capabilities from engineering and fabrication to on-site installation and commissioning.

-

Proven Track Record: Decades of experience completing complex ASU projects on time and on budget.

-

Safety Without Compromise: Industry-leading safety performance with zero-incident targets.

-

Specialized Expertise: Deep knowledge of cryogenic separation systems, piping, and process integration.

CONTACT US

Call us today to speak with one of our Air Separation specialists: +1 (317) 870-2400 or click to contact us below:

Industries We Serve

|

Industrial Gas Production |

Steel & Metals Processing |

Chemical & Petrochemical |

Energy & Power Generation |

AIR SEPARATION CONSTRUCTION PROCESS

-

Why MIG?MIG’s integrated teams of experienced licensed craftsmen, professional engineers, and highly trained workforce, along with its seasoned leadership team have earned a reputation for consistently delivering the highest quality solutions and services - at competitive prices – while maintaining an impeccable safety record.

Our experienced team of project managers, professional engineers, certified welders and fabricators, certified riggers, millwrights, pipefitters, valve technicians, specialty machinists, and support personnel deliver our services to the highest standards of quality and safety, improving facility reliability and performance—and supporting greater profitability for your plant.

Our ability to respond quickly to critical equipment failure and repair needs and deliver rapid response for confined space emergencies is unmatched.

-

Planning & Engineering

Every air separation unit construction project begins with careful planning and engineering.

Our teams cover piping, mechanical, civil, structural, process, electrical, instrumentation, and controls.

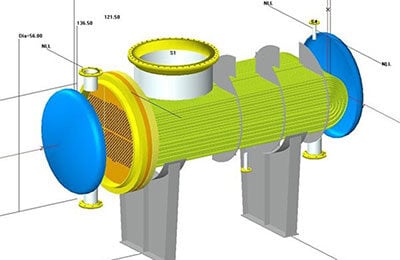

We design and review pressure vessels, heat exchangers, distillation columns, tanks, and other equipment critical to air separation construction. This ensures safety, code compliance, and a clear path to efficient installation.

-

Fabrication

During the fabrication phase, MIG produces the specialized components needed for air separation unit construction. We work with stainless steel, carbon steel, aluminum, and other alloys, building vessels, tanks, piping, and exchangers to ASME and NBIC standards. Our welds and assemblies are tested and inspected to guarantee long-term reliability. Whenever possible, modules are shop-built to shorten on-site air separation construction schedules.

-

Site Preparation & Installation

Site work for air separation construction begins with civil foundations, utilities, and layout. Civil, mechanical, and electrical work is completed to exacting standards to ensure long-term reliability. MIG installs cold boxes, brazed aluminum heat exchangers, vessels, piping systems, and control infrastructure. Mechanical, electrical, and instrumentation crews coordinate closely to keep the project on track. Safety is central in all rigging, lifting, and installation activities during air separation unit construction.

-

Commissioning & Testing

After installation, we move into commissioning and validation. System start-up, performance testing, and operational hand-off are key steps in this stage. Pressure, flow, and thermal checks confirm that the air separation unit construction meets all design and safety requirements. Operators are trained, documentation is handed over, and adjustments are made so the system is fully production-ready.

-

QualificationsWe attribute our success to our experience in the industrial gas industry.

- WPS, PQR and Charpy Certified in stainless steel, carbon steel, aluminum, monel, or iconel

- National & international project experience

- Highly skilled, versatile teams

- Tenured professionals/technical staff.

- 60 FT qualified staff

- OSHA 10 & 30 trained.

- Proven project execution abilities.

- State-of-the-art fabrication shop, paint booth, storage, clean room, confined space rescue center

- Through our network of TransTech family companies we're able to leverage over 300,000 sq. feet of fabrication facility space nationwide, including TX, NC, IN, and OR locations, to support rapid, efficient project delivery

- Strong emphasis on safety – EMR .68; 'A' rating with ISNetworld

.png)

FREE Download: Capabilities & Services Flip Book

Our Specialized Services for Essential Industrial Infrastructure - Capabilities & Services Flip Book includes:

- Complete Overview of MIG's Capabilities & Services

- Engineering Services Overview

- Detailed Review of Fabrication Capabilities & Materials

- More

AIR SEPARATION SOLUTIONS SPECIALISTS

-webp.webp?width=300&height=232&name=MIG%20Flipbook%20Cover%20w%20Shadow%20(1)-webp.webp)